Serial N0. 17

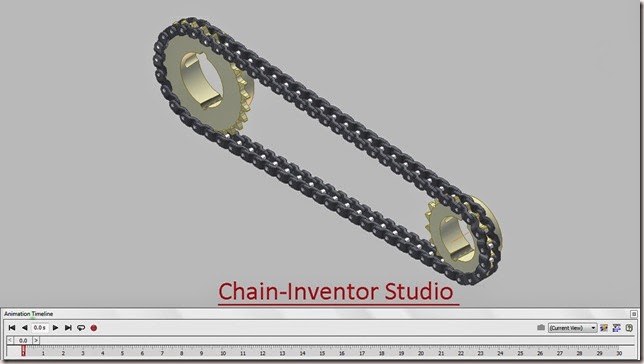

In this Autodesk Inventor tutorial, we will learn how to create an animation of chain links similar to what we see in the real world. For this, we will use a chain link (total 61 after duplicating it by using Assembly components pattern tool ) and two sprockets.

While creating the animation we will use as well learn various tools and functionalities of the software like basic sketching, creating user-defined work planes and points, utilization of adaptivity features, application of pattern feature along with detailed settings, Assembly Mates, Inventor Studio etc.

While creating the animation we will use as well learn various tools and functionalities of the software like basic sketching, creating user-defined work planes and points, utilization of adaptivity features, application of pattern feature along with detailed settings, Assembly Mates, Inventor Studio etc.

Video:--

Length of One Chain-Link

Loop length of Chain Profile

Related Blog Post

Dear viewers an advance version of Chain Animation tutorial showing the animation of 70 Chain Links along with 3 Sprockets can be seen on the following link…

Chain-Inventor Studio (Upgraded Design) - Autodesk Inventor 2013

Please check out some more works by us on Autodesk Inventor below--

Chain-Inventor Studio (Upgraded Design) - Autodesk Inventor 2013

Please check out some more works by us on Autodesk Inventor below--

Basic tutorials on Autodesk Inventor by us:—(YouTube Playlist of more than 15 videos.)

Detailed tutorials on Autodesk Inventor by us:—(YouTube Playlist of more than 150 videos.)

Hope all of you enjoyed the tutorial. If you find the video useful please like it and share it with your friends/colleagues and do not forget to Subscribe us to get latest updates about our new uploads.

Click to Subscribe us on YouTube

Dear Viewers if you like our work and wanted to support us, to keep continuing the good work, then become a patron of ours at ‘Patreon’ site. Patreon is a simple way for you to contribute to the creator’s work every month/ every time they release their new work and get rewards in return. Please visit the following link to know all about our work and what we are offering as a reward to our patrons…

I'm having a problem when I try to do this. The chain links that wrap around the sprocket at the curve don't curve and remain horizontal like the rest of the links which are flat. ie, the angle between all of the horizontal planes of every link is 0.

ReplyDeleteYa this is a bit difficult one. If some thing gives error start from the scratch it will be created in the end. Many people report this type of problem first and then succeed.

ReplyDeleteGreat! thank you for the download link!

ReplyDelete